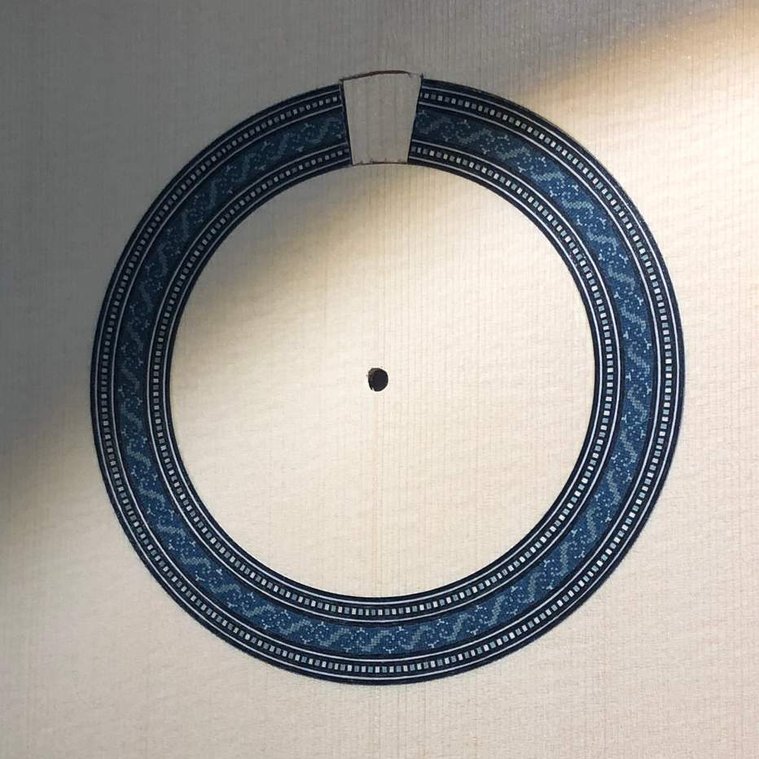

the rosette

Originally designed to reinforce the sound hole, the rosette is now one of, if not the most creative aspect of the guitar. Most luthiers have one design for all of their guitars which acts as a signature. However, since the very beginning of my guitar making journey, I decided to make a completely unique rosette for every guitar, which gives each of my guitars their own theme and identity.

When building a guitar for a specific client, I work closely with them to design a rosette which fits their own personality and interests so their custom guitar feels even more like their own.

The design and creation of a rosette is about thirty to forty hours of work.

Below you can see how a rosette comes together

It starts with a design

Each square in the drawing represents a 0.5x0.5mm square of natural or dyed veneer.

We cut strips of veneer to make up each of the unique columns in the design.

Before the rosette can come together, there must be rings to surround the tiles. I usually make my rings out of several straight veneer strips with a special inlay in the middle